Linen Filtering

Keeping RFID Linen seperated from non-rfid linen in a large commercial laundry can be an impossible task, especially when the linen is otherwise identical.

The goal was to develop a suite of tools to be used on the laundry floor to allow staff to quickly discern which products were RFID enabled, and seperate them as needed.

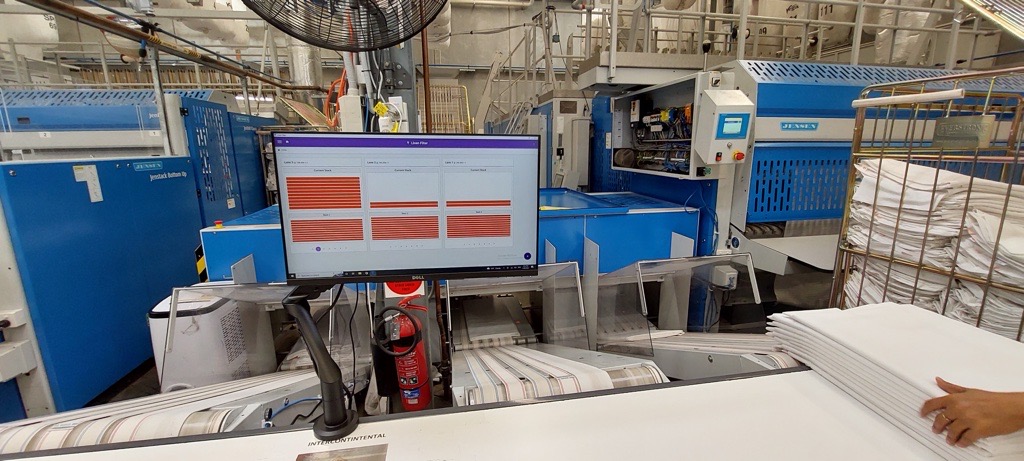

The key was to ensure that we minimised extra innovations required, so as not to impact operational efficiency when processing the linen.

A major takeaway from this project was the importance of ensuring the technology empowered employees to do their job, rather than hinder it

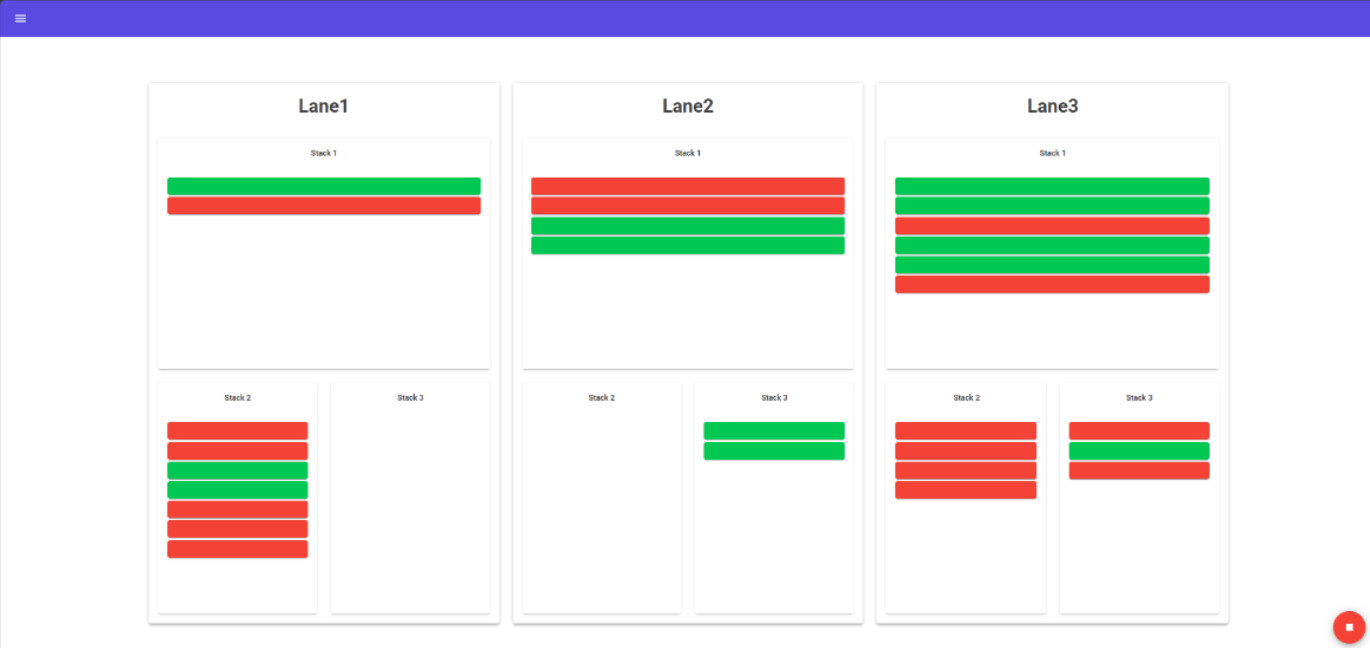

The tools created a binary indicator of RFID status at the place where it was easiest for the employee to sort it, should they need to.

For sheets this was a red/green indicator mapped to the bundle of linen they were receiving off the stacker conveyor. Making it easy for them to remove non-rfid sheets.

For pillowcases this was an LED indicator that illuminated in the presence of an RFID tag in the hem. The employee simply sets aside any pillowcases that do not trigger the LED.

Linen filtering is still in its infancy, but I was proud to be able to contribute to the beginning of a long road ahead in simplifying RFID operations on the laundry floor.